Today I made a pair of bench dogs that I don’t need. But I had to make them. For the past few years I’ve been pulling together notes and stories left by some of the people who taught me woodworking. It’s an on-going project and I’m not even sure what the end result (a book) will consist of. I still have a lot of research to do for it but am at the same time sorting what I have. Among the latter are notes left by two of these people - Jennie Alexander (1930-2018), who many have heard of, and Daniel O’Hagan (1923-2000) who is decidedly less-well-known. I met them both through Drew & Louise Langsner in the 1980s.

Daniel was a huge influence on me and many others. I have worked with his family who kindly gave me access to his shop notes, which are quite extensive. Because I don’t know the whole story yet, I’m not going to try to tell it here. Wait for the book. But among Daniel’s notes was a paper pattern for some bench dogs that he saw in the shop of Walter Liebich in 1966. I traced the pattern and stashed it in the shop, thinking “someday...” Then yesterday I saw a video of Walter using these dogs while making some chairs. I decided today was the day. “Shit or get off the pot”, I heard my mother saying.

I made the dogs to fit the rectangular mortises in my German workbench. The notion is simple, they have points in their inner faces, like a lathe. One is in the bench, the other in the tail vise. Pinch your workpiece between them and shave the full length - no flipping it end for end like a shaving horse. Don’t have to wind and unwind the vise to reposition the stock. Just turn it.

I chose white oak, thinking its toughness will be a benefit. There’s bound to be some stress on these things as you crank the vise to engage the workpiece. I cut the tenons while the stock was still squared, cutting the curves after the pieces fit in the bench. I used a bowsaw/turning saw to rough out the shapes. If you don’t have one you can make kerfs along the insides of the curves and chop out the waste with a chisel.

I thought I’d stop when I got to setting points in the dogs - figuring I didn’t know what to do so I’d wait. But I knew if I shelved this project today a lot of time could go by before I took it up again. So I just cut a 10d nail, bored a pilot hole and knocked it in there.

Tested it for all of three minutes - feels like it could be fun. I used a center punch to make a divot in each end of the stock, same as I was turning it. I am not giving up my shaving horse but this setup has some benefits - mentioned above.

But that’s not why I made it. Poring over these notebooks and other papers of JA & Daniel has me thinking about why they wrote everything down. One was to remind themselves when the next time came around for a given project or technique. But surely one was to hand it down. To us. Then on from there. When Daniel’s friend Walter died in 2008 at age 79 his obituary said he’d worked for 60 years. He was born in the area around the Germany/Poland border. He appears several times in Daniel’s notes, I’ll learn more about him as time goes on.

I’ve seen variations on this sort of shaving setup before, often used for shaving tool handles. JA used to mess around with adaptations of it, some appear in the 1978 edition of her book Make a Chair from a Tree. Below is a shot of JA back then working with a pipe clamp version. These were often convoluted. Hard to reach the full length of that stock while sitting with that pipe clamp in your lap…no wonder this contraption faded away.

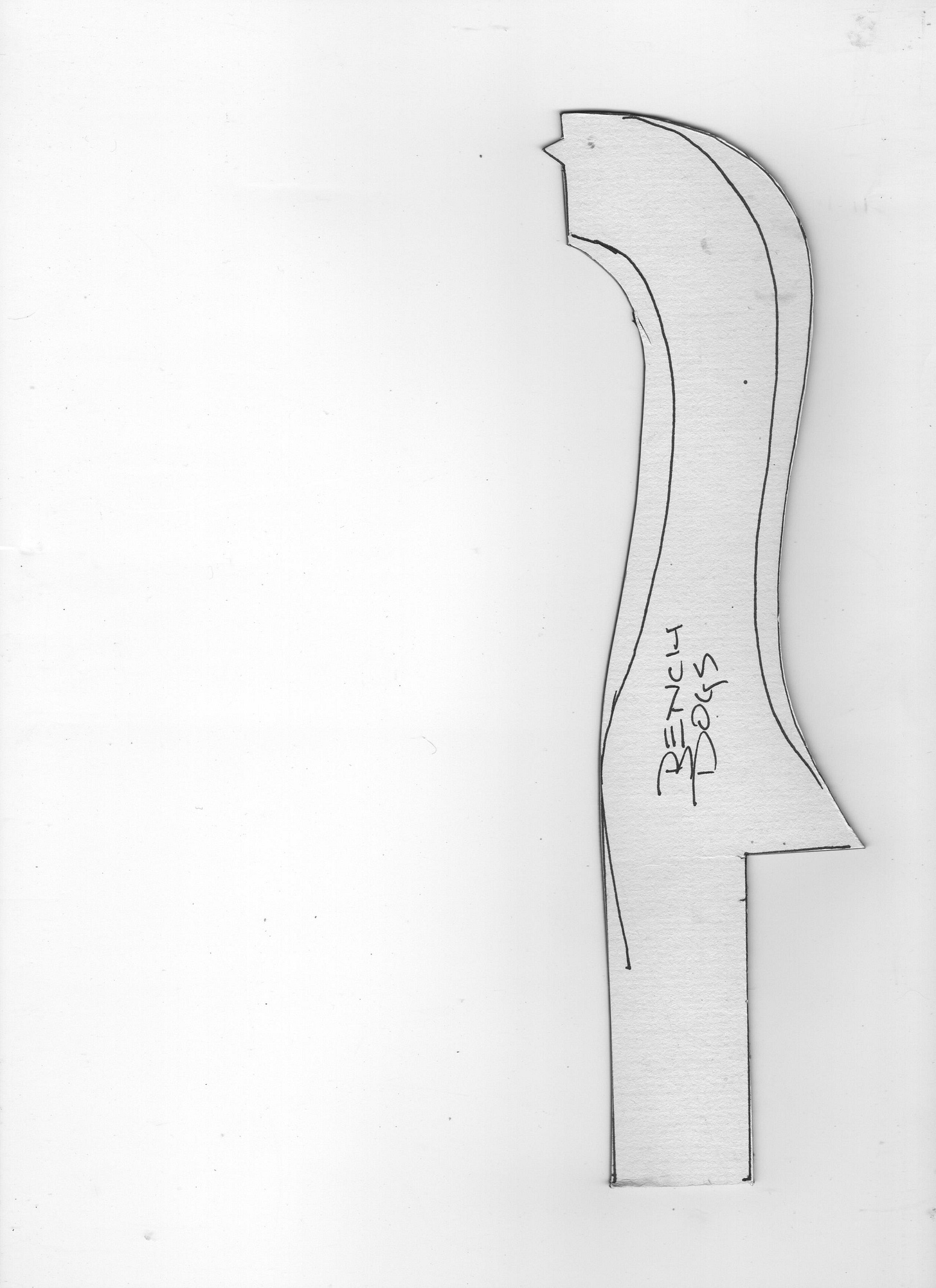

But the Walter/Daniel setup simple. If you’d like to make them - you can wing it, but here’s the pattern I used. Make the tenon to fit your dog holes. I made mine about 1 1/4” thick, with narrow shoulders on the sides and a 1”+ shoulder behind. Not sure how Walter’s fit in his bench, where the shoulders were, etc. So far, this works. The height of the dog above the bench is about 6 5/8”- 6 3/4”. You could experiment with taller or shorter versions.

And finally - the youtube video showing Walter Liebich - it’s only the first 4 minutes or so that I’m interested in -

I look forward to making these! I have a couple of canes to make for my parents, and a future’s worth of making chair legs.

First application that's made me consider putting a tail vice on the new workbench I'm building.

And some nice square dog holes to go with it.

Till now, when making octagonal legs, I've messed around with sash clamps in my leg vice, but it's a pain.